Solutions & Services

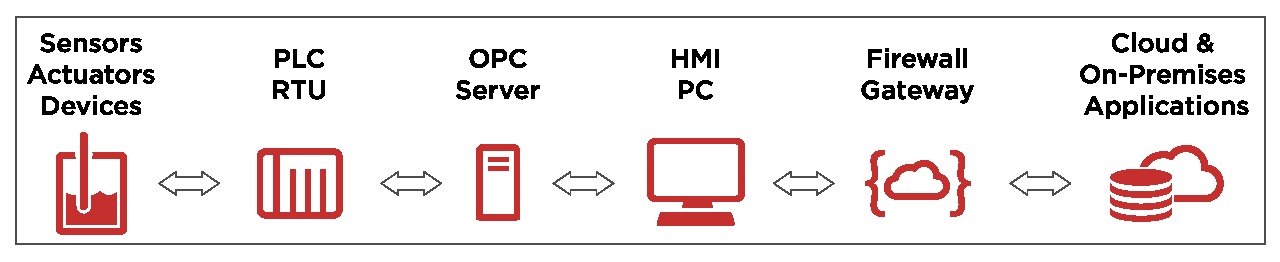

Integration solution services - OPC

groov EPIC System SNAP PAC System

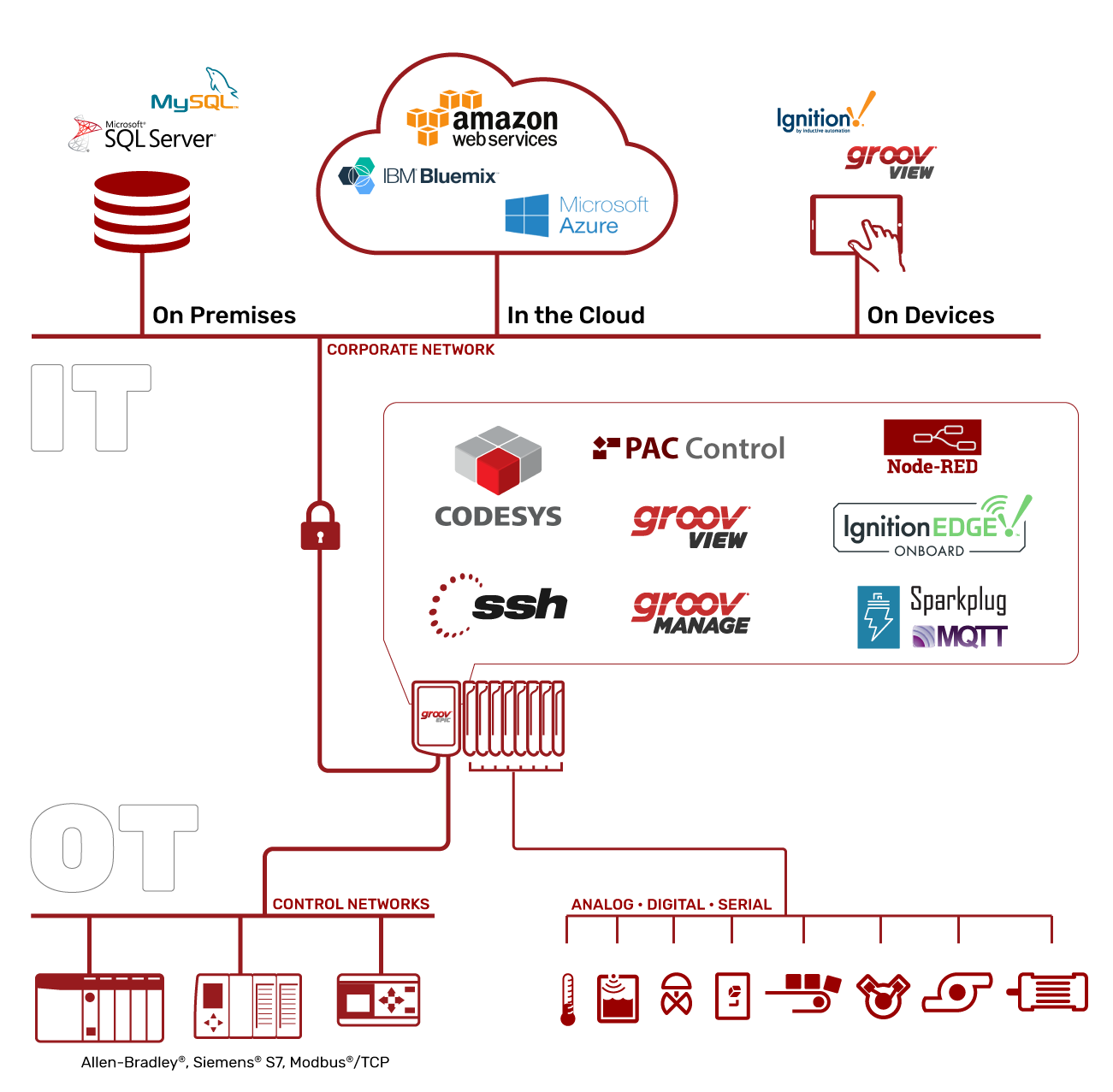

Temco is expert in system integration solutions. No matter what kind of SCADA (Supervisory Control And Data Acquisition) system like: Johnson Controls - Metasys, Honeywell - Alerton, Trane – Tracer Summit, even industrial PLC (Programmable Logic Controller) such as Opto22 – PAC and AB. , we are capable of implementation of the advanced OPC technologies to integrate different systems into an entire converged network for operation.

As matter of fact , the OPC (Object Linking and Embedding Service for Process Control) is one of the most commonly used integration solution in the industry for the existing SCADA / BMS system.

Selecting and well configuring a compatible OPC Server with your existing SCADA / BMS is the first step for the solution. Next to come is to define features you want to embed into the system. We can provide tailored made OPC solution according to your specific requirement.

Benefits of Integration Solutions

To extend your existing SCADA system to extreme, using our Integration solutions, you can achieve following advantages:

- System / Data interoperability

- Perfect Data Analysis

- Efficient

- System sustainability

- Security

- Incorporate other features by 3rd party software developers

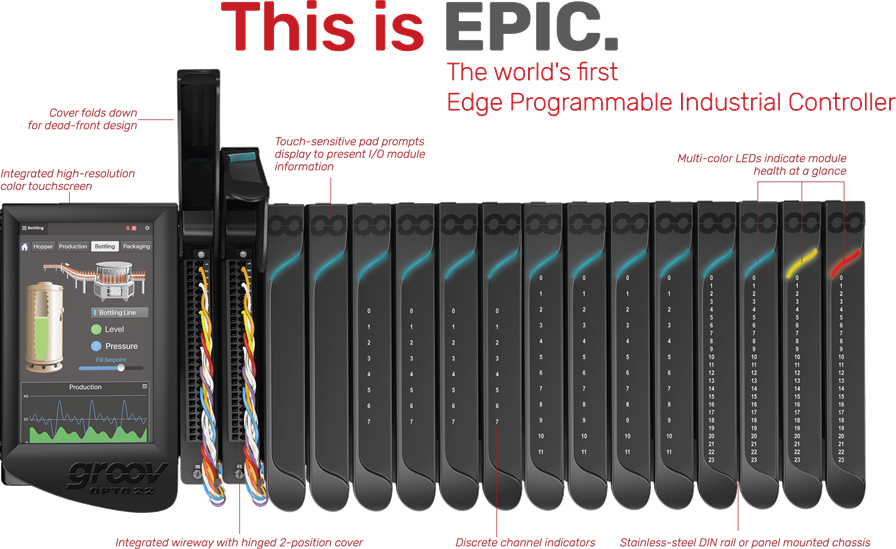

groov EPIC System

What is groov EPIC System?

It’s an Edge Programmable Industrial Controller (EPIC), and the acronym says it all.

Check out the FCI Watermakers Case Study - FCI is using groov EPIC with PAC Control and groov View with great results.

CHALLENGE:

SOLUTION:

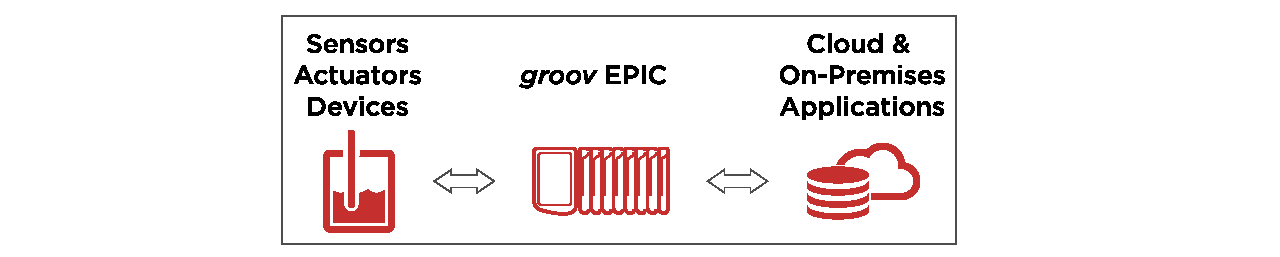

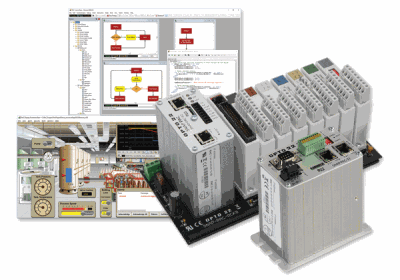

An edge programmable industrial controller, groov EPIC is much more than a PLC or a PAC. We designed it from the ground up as both a reliable real-time industrial controller and a processor to collect, process, display, and exchange data.

groov EPIC talks directly to field devices, other control systems, databases, cloud services, and a lot more. EPIC helps solve the challenges of complexity, security, and cost.

- One industrial unit takes the place of all that middleware.

- Encryption, user authentication, and communication options help you implement a more secure system.

- Getting data where you need it is faster and easier with built-in, easy-to-use software.

groov EPIC Software

Configure, commission, and troubleshoot your EPIC controller, I/O, and networking with groov Manage. Use it locally on the EPIC processor's high-resolution touchscreen, or on your computer, smartphone, or tablet.

Program your groov EPIC with easy-to-use automation software PAC Control. Flowchart-based with optional scripting, PAC Control has 500+ plain-English commands for process control, remote monitoring, and more.

Or program your groov EPIC for industrial control and monitoring using any familiar IEC 61131-3 compliant language and the CODESYS Development System. Mix languages as needed for your application.

Build and view operator interfaces to monitor and manage your system from any device with a web browser, from a smartphone to an HDTV. No tag or user limits; user authentication and data encryption; trends, events, and notifications.

Extend the Ignition Platform to the edge of your network with Ignition Edge®, a product of Inductive Automation®. Includes drivers to Allen-Bradley®, Siemens®, and Modbus®/TCP devices.

Improve communications efficiency and reduce reliance on IT with MQTT/Sparkplug. IIoT project implementation is simpler using a publish/subscribe architecture.

Build simple flows to move data to and from databases, cloud applications, and APIs using Node-RED. Leverage a large library of more than 600 pre-built nodes to process data.

Build your own custom applications using languages you know like Python, C/C++, and others, and run them on an open, Linux®-based automation system.

SNAP PAC System

Opto 22's SNAP PAC System is an integrated system of hardware and software for industrial control, remote monitoring, data acquisition, and Internet of Things (IoT) applications.Opto 22's SNAP PAC System.

Consider the SNAP PAC System for your next project:

- Simple to understand and use

- Lower capital and long-term costs

- One system for many automation projects

- Advanced programming tools

- Connectivity to third-party software and devices

- The best I/O in the business

Four Integrated Components of the NAP PAC System

- PAC Project™ Software Suit

- easy-to-use flowchart-based control programming, HMI (human-machine interface) development and runtime, plus optional OPC server, database connectivity software, and software-based controller for PC-based control

- SNAP PAC controllers

- standalone or rack-mounted industrial controllers with networking options and a RESTful API, or a software-based controller

- SNAP PAC brains

- intelligent I/O processors for distributed control on Ethernet (wired and wireless) and serial networks

- SNAP I/O™

- analog, digital, and serial I/O modules for connecting to field devices, machines, and sensors These four simple but flexible components form a system capable of handling any application from basic equipment monitoring to complete factory automation.

Software

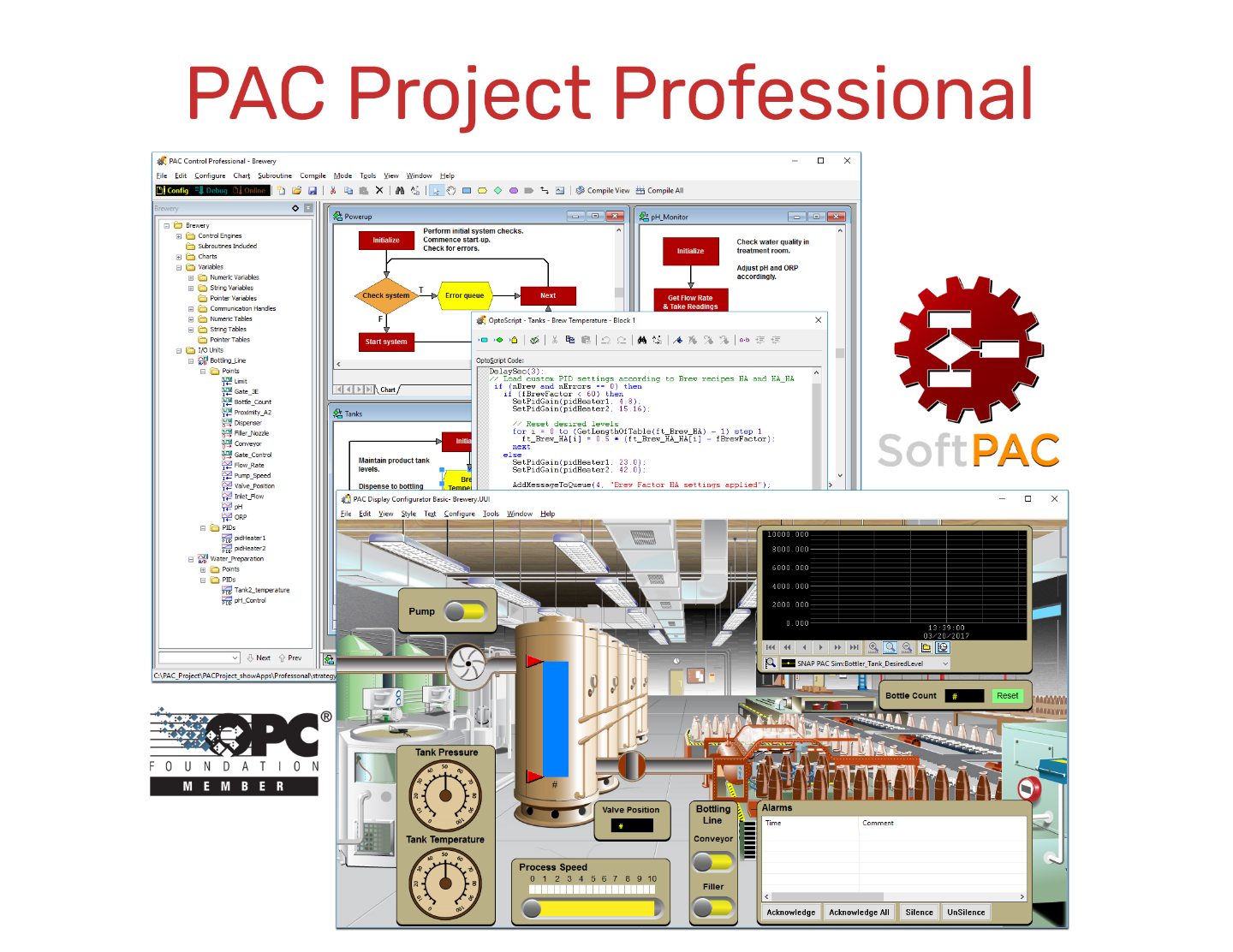

For software, choose between two forms of the PAC Project Software Suite: PAC Project Basic and PAC Project Professional.

PAC Project Basic is free and can be downloaded from www.opto22.com. PAC Project Basic includes everything you need for most control and monitoring applications: control programming, HMI creation, and I/O configuration software.

PAC Project Professional is available for purchase. The Pro version adds OPC communication, database connectivity, and support for both Ethernet link redundancy and controller redundancy. Legacy hardware is also supported, with a SNAP PAC S-series controller.

Document

Reference:

FOR ADDITIONAL INFORMATION, contact us for complete solutions and an opportunity to let TEMCO Technologies serve you with professional expertise.