HVAC Control Products

Valve and Actuator

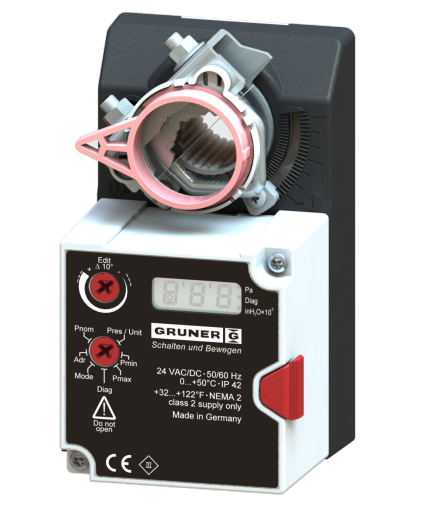

Gruner

Rotary actuator for adjusting dampers in HVAC installations.

- Running time 60...120 s / 90°

- Torque 5 Nm

- Nominal voltage 24 VAC/DC

- Control 2-/3-point

- Damper size up to approx. 1 m²

- Shaft coupling clamp ◊ 8-12 mm / Ø 8-16 mm

Rotary actuator for adjusting dampers in HVAC installations

- Running time 20 s / 90°

- Torque 5 Nm

- Nominal voltage 24 VAC/DC

- Control 2-/3-point

- Damper size up to approx. 1 m²

- Shaft coupling clamp ◊ 8-15 mm / Ø 8-20 mm

- Running time 1 s / 90°

- Torque 2 Nm

- Nominal voltage 24 VAC/DC

- Control continuous control (0)2...10 VDC

- Damper size up to approx. 0.4 m²

- Shaft coupling clamp ◊ 8-15 mm / Ø 8-20 mm

Spring return actuator for adjusting dampers in HVAC installations

- Running time motor 75 s / 90°

- Running time spring g 20 s / 90°

- Torque motor 10 Nm

- Torque spring 10 Nm

- Nominal voltage 24 VAC/DC

- Control 2-point

- Damper size up to approx. 2 m²

- Shaft coupling clamp ◊ 9-18 mm / Ø 9-26 mm

Rotary actuator for pressure and volumetric flow control

- Running time 100 s / 90°

- Torque 5 Nm

- Nominal voltage 24 VAC/DC

- Nominal voltage (0)2...10 VDC

- Sensor 250 Pa (dynamic)

- Damper size up to approx. 1 m²

- Communication PP-Bus

- Shaft coupling clamp ◊ 8-15 mm / Ø 8-20 mm

Rotary actuator for adjusting air dampers for pressure control in HVAC installations

- Running time 100 s / 90°

- Torque 5 Nm

- Nominal voltage 24 VAC/DC

- Control (0)2...10 VDC

- Sensor 300 Pa (dynamic)

- Damper size up to approx. 1 m²

- Communication PP-Bus

- Shaft coupling clamp ◊ 8-15 mm / Ø 8-20 mm

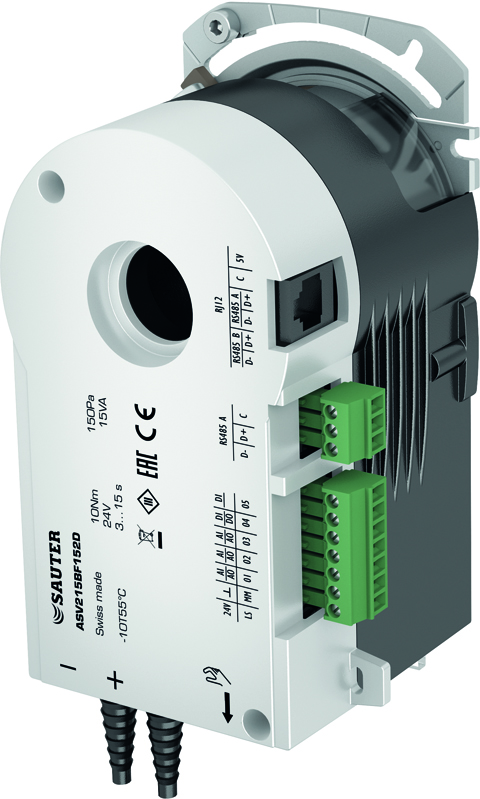

Sauter

Allows demand-based volume flow control in order to optimise energy consumption in ventilation systems. Differential pressures of at least 1 Pa can be controlled to allow minimal volume flows at the lowest duct pressure and energy consumption.

- Controlling the return air in fume cupboards and controlling the supply and return air in laboratories, clean rooms, hospital wards and operating theatres using a VAV box or a damper and flow probe

- Static measurement of differential pressure based on the capacitive method of measurement

- Zero point can be calibrated using software

- djustable end values of the differential pressure measuring range

- 50…150 Pa

- 100…300 Pa

Absolutely no losses through leaks. Energy is restrained.

- Regulation of heating zones, air secondary-treatment units and fan coil units in combination with AXT 211, AXS 215S or AXM 217(S)

- Flat-sealing standard version or version with clamping-ring screw fitting for pipe Ø 15 mm with DN 10

- Valve with male thread as per DIN EN ISO 228-1, class B

- Stuffing box can be replaced under system pressure

- Control passage A–AB is closed when the spindle is moved in

- Closing procedure against the pressure

Linear mixture and no loss through leakage in the control passage for energy-efficient regulation

- Flat-sealing standard version or version with clamping-ring screw fitting for pipe Ø 15 mm with DN 10

- Valve with male thread as per DIN EN ISO 228-1, class B

- Special model for fan coil units with cast-on by-pass T-piece

- Control passage A–AB is closed when the spindle is moved in

- Can be used as a control valve and, thanks to its tight-sealing third passage, as a distribution valve

- Nickel-plated valve body made of cast brass

Reliable actuation in efficient control systems

- Fitted to the valve using no force thanks to the Low-Force-Locking (LFL) connector

- Fitted onto valve with M30 x 1.5 thread with automatic adjustment of closing dimension

- Pushing force max. 125 N

- With 230 V or 24 V thermal expansion element

- Large visible position indicator

- NC “normally closed” and NO “normally open” models (with and without auxiliary contacts)

Efficient use in continuous control systems

- Continuous control of cold and hot water in closed circuits

- Water quality as per VDI 2035

- In combination with valve actuators AVM 105(S), AVM 115(S), AVM 321(S) and AVF 124 and AVF 125(S) as a control unit

- Not suitable for steam or drinking water or potentially explosive atmospheres

- Valve with flange connection as per EN 1092-2, seal form B

- Regulating valve, free of silicone grease, painted black

Efficiency means precise and reliable control

- Continuous control of cold and hot water in closed circuits

- In combination with valve actuators AVM 322(S), AVM 234S, AVN 224S and AVF 234S as a control unit

- Water quality as per VDI 2035

- Valve with flange connection as per EN 1092-2, seal form B

- Nominal pressure 25 bar, except BUG065F316, nominal pressure 16 bar

- Not suitable for drinking water

Automatic adaptation to valve, optimal operator convenience, precision activation and high energy efficiency with minimal operating noise

- In ventilation air conditioning units for actuation of 2- and 3-way valves of type series AVM 321: VUD, VUE, VUN, BUD, BUE, BUN and AVM 322: V6R, VQD, VQE, VUG, VUP, VUS, B6R, BQD, BQE, BUG, BUS

- For controllers with a switching output (2-point or 3-point control)

- Synchronous motor with electronic control unit and load-dependent cut-off

- Direction of operation and positioning time can be set using coding switches

Torque-dependent cut-off facility for efficient usage of energy

- For controllers with switching (2- and 3-point) or continuous output (0…10 V)

- Self-centring spindle adapter

- Gear unit can be disengaged to position the damper and for manual adjustment

- Stepping motor with electronic activation and cut-out

- Maintenance-free

- Intelligent adaptation of rotation angle, incl. feedback adjustment